NEWS

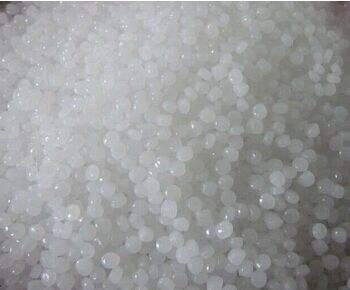

APPLICATION OF UHMWPE IN BULLET PROOFING

Writer: admin Time:2020-03-07 17:04 Browse:

Since the 1960s, the development of bulletproof vest is very rapid, the weight is gradually reduced and the performance is gradually enhanced. The development of bulletproof vest has gone through two stages: the hardware bulletproof vest and the software bulletproof vest. The former is eliminated by the latter due to its poor wearing comfort. Soft body armour is made from Kelver fibre, carbon fibre and Spectra (commercial grade of UHMWPE fibre) fibre. Spectra fibers due to their low density. The bulletproof performance is good and receives the universal attention. Spectra's structure and properties determine the properties of the Spectra fiber body armor, which is waterproof, non-reactive to chemical media, and able to withstand a barrage of bullets. Therefore, both weight and bulletproof ability are better than previous materials.

Existing Deficiencies and Improvement Measures

UHMWPE fiber as bulletproof material has the following deficiencies:

UHMWPE fiber as bulletproof material has the following deficiencies:

- High crystallinity and orientation degree,

- Small macromolecular cross-sectional area,

- Nonpolar properties make it difficult to wetting, does not react with matrix,

- Does not produce crosslinking,

- Poor interface effect,

- Low melting point,

- High temperature strength.

Therefore, in the application of UHMWPE fiber to make bulletproof materials or structural materials, it is often necessary to modify or surface treatment, in order to improve its interface performance.

PRODUCTS

NEWS

CONTACT US

Mob/Whatsapp: +86-15036793056

Phone: +86-37962306300

Fax: +86-37960406316

Email: export@lysinopipe.com

Add: National New & High Tech Industry Development Zone ,Luoyang ,CHINA