SELF FLOATING DREDGING HOSE

SELF FLOATING DREDGING HOSE

- Product ID:SELF FLOATING DREDGING HOSE

- Phone: +86-15036793056

- WhatsAPP: +86-15036793056

- Email: export@lysinopipe.com

- Payment term: TT/LC/Western union

- send inquiry

Self-floating Dredging Hose

Description

Sinopipe’s Dredge Self-floating Discharge Hose is widely used in dredging project. It is a major part of a floating pipeline. It can be used for transporting gravel,slurry,clay,sand,etc.Self-floating discharge hose consists of an inner discharge hose and buoyancy layer.This kind hose can self-float on the water surface.

Various designs can be available,such as Dredge Tapered Self-floating Hose and Dredge Armored Self-floating Hose. Armored Self-floating Hose is a new type. It is more abrasion-resistant and has longer service-life than other ordinary self-floating hose.It can be used for transporting sharp gravel,coral reefs,etc.Steel rings are embedded in the inner layer.

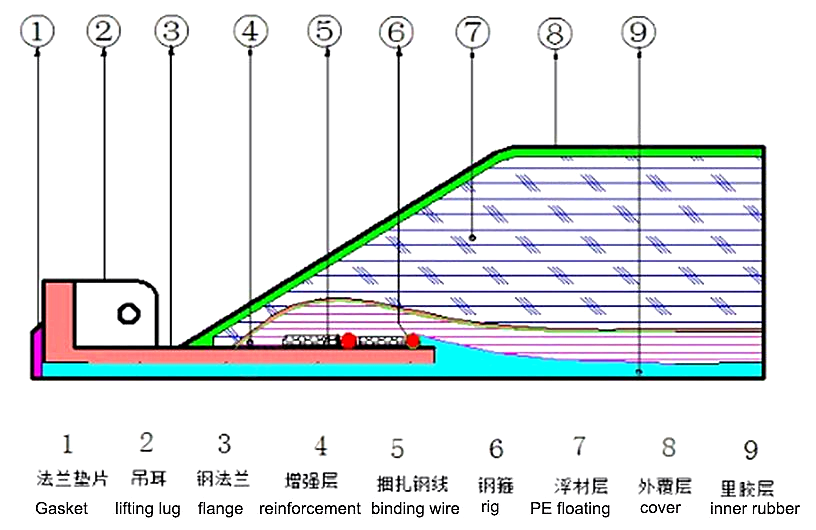

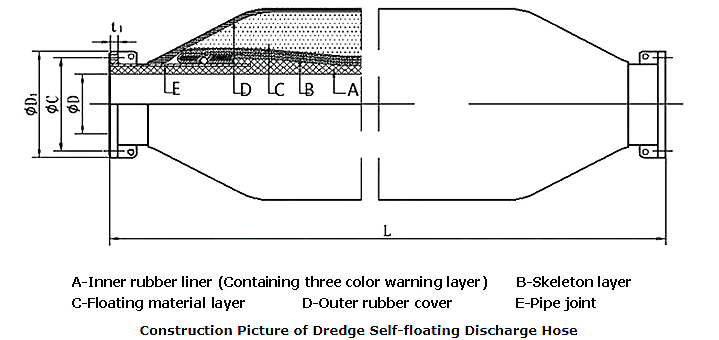

Structure

Internal rubber layer:high-quality NR, SBR, BR

Inner rubber layer thickness: 15-45mm

Floating layer: PE

Reinforcement layer:strong tire cord and Floating material layer

External rubber layer--SBR and CR blend

Length:usually 5.8m or 11.8m or at customer's request

Features

※Good wear resistance of the inner layer.

※Colored indicator in the inner layer.

※Outer cover with excellent abrasion resistance and UV protection.

※Single foam flotation casing to prevent water absorption.※

※The hose emergence above water is not less than 20% of the total volume.

※Flang design according to customer's requirement.

※Bending angle : 0°-45° ( Maximum: 90° in short time ).

※The hose has two sides,so can take turns using it.

※Easy to install, of good adhesion, long service life.

Floating hose Section

Sinopipe Self floating Hose Size Table

| ID(mm) | Working Pressure(Mpa) | Burst Pressure(Mpa) | Length(mm) | Min Bending Radius | Wear Layer Thickness (mm) | Cover Thickness(mm) |

| 150 | 0.5-1.0 | 1.5-3.0 | 11800 | 8D | 10~20 | 8~12 |

| 200 | 0.5-1.0 | 1.5-3.0 | 11800 | 8D | 10~20 | 8~12 |

| 250 | 0.5-1.0 | 1.5-3.0 | 11800 | 8D | 10~20 | 8~12 |

| 300 | 1.0-2.0 | 3.0-6.0 | 11800 | 12D | 12~25 | 10~15 |

| 350 | 1.0-2.0 | 3.0-6.0 | 11800 | 12D | 12~25 | 10~15 |

| 400 | 1.0-2.0 | 3.0-6.0 | 11800 | 12D | 12~25 | 10~15 |

| 450 | 1.0-2.0 | 3.0-6.0 | 11800 | 12D | 12~25 | 10~15 |

| 500 | 1.0-2.0 | 3.0-6.0 | 11800 | 12D | 12~25 | 10~15 |

| 600 | 1.5-2.0 | 4.5-6.0 | 11800 | 15D | 20~30 | 12~15 |

| 650 | 1.5-2.0 | 4.5-6.0 | 11800 | 15D | 20~30 | 12~15 |

| 700 | 2.0-2.5 | 6.0-7.5 | 11800 | 15D | 30~50 | 15~18 |

| 750 | 2.0-2.5 | 6.0-7.5 | 11800 | 15D | 30~50 | 15~18 |

| 800 | 2.0-2.5 | 6.0-7.5 | 11800 | 15D | 30~50 | 15~18 |

| 850 | 2.0-2.5 | 6.0-7.5 | 11800 | 15D | 30~50 | 15~18 |

| 900 | 2.5-3.0 | 7.5-9.0 | 11800 | 15D | 30~50 | 18~20 |

| 1000 | 2.5-3.0 | 7.5-9.0 | 11800 | 15D | 50~75 | 18~20 |

| 1100 | 2.5-3.0 | 7.5-9.0 | 11800 | 15D | 50~75 | 18~20 |

|

Other specifications required by customer |

||||||

PRODUCTS

NEWS

CONTACT US

Mob/Whatsapp: +86-15036793056

Phone: +86-37962306300

Fax: +86-37960406316

Email: export@lysinopipe.com

Add: National New & High Tech Industry Development Zone ,Luoyang ,CHINA