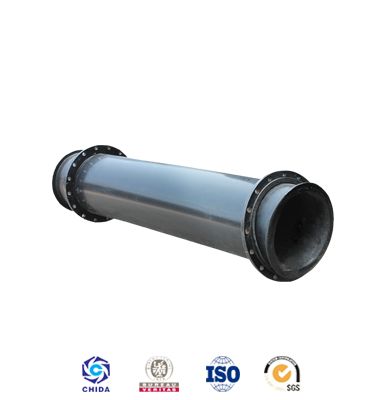

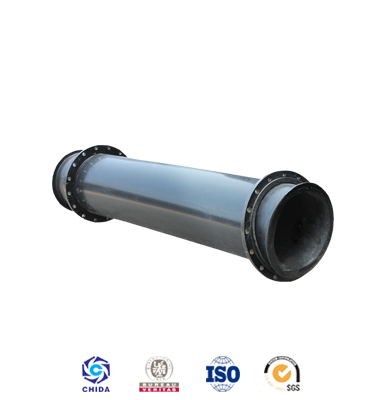

UHMWPE DREDGING PIPE

UHMWPE DREDGING PIPE

- Product ID:UHMWPE DREDGING PIPE

- Phone: +86-15036793056

- WhatsAPP: +86-15036793056

- Email: export@lysinopipe.com

- Payment term: TT/LC/Western union

- send inquiry

UHMWPE Dredging Pipe

Ultra-high molecular weight polyethylene (UHMW full name is ultra-high molecular weight polyethylene pipe) is a thermoplastic engineering plastics with an average molecular weight greater than 1.5 million, which is polymerized by ethylene and butadiene monomer under the action of a catalyst.

Sinopipes's Ultra high molecular weight polyethylene (UHMWPE) pipe adopts ultra high molecular weight polyethylene resin which molecular weight is more than 2,500,000.Processed after continuous extrusion molding, it is suitable for mining, power, coal, chemical and other special industrial and mining enterprises.

Due to its high wave impact resistance,sea water chemical resistance and ultraviolet resistance,UHMWPE pipe is especially ideal to be applied in sea water environment such as dredging industry.

Product Characteristics

※Extremely high wear resistance--6.6 times higher than normal alloy steel, 27.3 times that of stainless steel, 6, 4 times that of polyethylene.

※Very high impact resistance--highest impact resistance among all plastics.

※Corrosion resistance--can be used in the concentrated hydrochloric acid, sulfuric acid and nitric acid.

※Good self-lubrication--frictional coefficient (196N, 2 hours) is only 0.219MN/m (GB3960).

※unique resistance to low temperature--can be used within -269 to 80℃.

※Not easy to form dirt--excellent surface non-adhesion and surface smoothness makes internal wall not easy to scale.

※Long life-span--still maintain more than 70% mechanical properties after it is buried and used for 50 years.

※Easy installation--Hard as diamond,light as paper.

| OD |

SDR26 0.6Mpa |

SDR21 0.8Mpa |

SDR17 1Mpa |

SDR13.6 1.25Mpa |

SDR11 1.6Mpa |

SDR9 2Mpa |

| Φmm | Thick(mm) | Thick(mm) | Thick(mm) | Thick(mm) | Thick(mm) | Thick(mm) |

| 65 | 8 | 9 | ||||

| 89 | 8 | 10 | ||||

| 110 | 8 | 10 | ||||

| 133 | 8 | 10 | 12 | |||

| 140 | 10 | 12 | 14 | |||

| 159 | 8 | 10 | 12 | 15 | ||

| 205 | 8 | 10 | 12 | 15 | 18 | |

| 219 | 9 | 12 | 13 | 16 | 20 | |

| 250 | 10 | 12 | 15 | 19 | 23 | |

| 273 | 9 | 11 | 14 | 16 | 21 | 25 |

| 300 | 9 | 10 | 12 | 15 | 18 | 20 |

| 325 | 12 | 14 | 16 | 19 | 24 | 30 |

| 350 | 10 | 12 | 14 | 17 | 21 | 32 |

| 377 | 12 | 14 | 18 | 22 | 28 | 35 |

| 400 | 10 | 12 | 14 | 16 | 20 | 22 |

| 426 | 14 | 16 | 20 | 22 | 32 | |

| 530 | 16 | 18 | 26 | 32 | ||

| 560 | 16 | 22 | 27 | 33 | ||

| 630 | 19 | 22 | 30 | 37 | ||

| 652 | 20 | 26 | 32 | 38 | ||

| 710 | 21 | 27 | 34 | |||

| 800 | 23 | 31 | 38 |

PROPERTY TABLE OF UHMWPE PIPES

| Category | Item | UHMWPE | ASMT Test |

| Physical property | Relative molecular weight/10000 | 200-300 | D2857 |

| Density/(g/cm3) | 0.945-0.975 | D1505 | |

| Powder density/(g/cm3) | 0.46 | D392 | |

| Average particle size/μm | 100-200 | 一 | |

| Mechanical property | Breaking strength/Mpa | 40-45 | D638 |

| Break elongation/% | 300-400 | D638 | |

| Bending modulus/Mpa | 600 | D747 | |

| Impact strength/(Kj/m2) | >140 | D250 | |

| Rockwell hardness;/HRM | 40-60 | D747 | |

| Abrasion loss/(mg/1000times) | 70 | D1175 | |

| Thermal property | Melting point/ ℃ | 136 | D2117 |

| Heat distortion temperature/ ℃ | 85 | D648 | |

| Linear expansion coefficient/10-4℃-1 | 1.5-2.5 | D696 | |

| Thermal conductivity/[w/(m.k)] | 8.5 | D177 | |

| Electrical property | Volume resistivity/(Ω.cm) | 10 | D257 |

| Breakdown voltage/(Kv/mm) | 50 | D149 | |

| Dielectric constant/106Hz | 2.3 |

D150 |

PRODUCTS

NEWS

CONTACT US

Mob/Whatsapp: +86-15036793056

Phone: +86-37962306300

Fax: +86-37960406316

Email: export@lysinopipe.com

Add: National New & High Tech Industry Development Zone ,Luoyang ,CHINA