CORRUGATED PIPE

CORRUGATED PIPE

- Product ID:CORRUGATED PIPE

- Phone: +86-15036793056

- WhatsAPP: +86-15036793056

- Email: export@lysinopipe.com

- Payment term: TT/LC/Western union

- send inquiry

Corrugated Pipe

SINOPIPE provides the complete corrugated HDPE pipe product to meet all your HDPE drainage needs - the full range of diameters, single-wall and dual-wall productions, reinfored tupes and other options, for the best of your drainage project.

Applications

SINOPIPE's PE Corr-pipe is suitable for use in gravity flow drainage in DOT/capitol improvement, residential, commercial, recreational, agricultural and irrigation application.

Description

Its superior strength to weight ratio gives it as much as SN16 Ring Stiffness. Its Peeling Strength (20±5℃),N/cm ≥70 and TIR is no less than 10%. Its creep rate is ≤2 . Most importantly,SINOPIPE's Corr-pipe welding joint has a Tensile Strength of no less than 1460,and still shows no damage at this value.

Benefits

Sinopipe' Steel Reinforced PE Corr-pipe is better engineered for a more durable joint and long-lasting performance. Sinopipe Corr-PE pipe is:

Made from HDPE with steel strip reinforced in side.This structure make it have extremely big ring stiffness, which enable it to withstand huge surrounding pressure.

Expected to significantly exceed 100 years of design service life.

| Steel Belt Reinfored HDPE Corrugated Pipe | |||||||

| ID | Min ID(Avg) | Min Inner Thk | Min Wall Thk | Max Pitch | Min Belt Thk | Ring Stiffness | Min Anticorrosive Thk |

| 300 | 294 | 2.5 | 4 | 75 | 0.4 | ≥10 | 2.2 |

| 400 | 392 | 3 | 4.5 | 85 | 0.4 | ≥10 | 2.2 |

| 500 | 490 | 3.5 | 5 | 100 | 0.5 | ≥10 | 2.5 |

| 600 | 588 | 4 | 6 | 110 | 0.5 | ≥10 | 2.5 |

| 700 | 673 | 4 | 6 | 115 | 0.5 | ≥10 | 2.5 |

| 800 | 785 | 4.5 | 7.5 | 120 | 0.7 | ≥10 | 3 |

| 900 | 885 | 5 | 7.5 | 135 | 0.7 | ≥10 | 3 |

| 1000 | 985 | 5 | 8 | 150 | 0.7 | ≥10 | 3 |

| 1100 | 1085 | 5 | 8 | 165 | 0.7 | ≥10 | 3 |

| 1200 | 1185 | 5 | 8 | 180 | 0.7 | ≥10 | 3 |

| 1300 | 1285 | 5 | 8 | 210 | 1 | ≥10 | 3 |

| 1400 | 1385 | 5 | 8 | 210 | 1 | ≥10 | 3 |

| 1500 | 1485 | 5 | 8 | 220 | 1 | ≥10 | 3 |

| 1600 | 1585 | 5 | 8 | 230 | 1 | ≥10 | 3.5 |

| 1800 | 1785 | 6 | 9 | 230 | 1 | ≥10 | 3.5 |

| 2000 | 1985 | 6 | 9 | 235 | 1 | ≥10 | 3.5 |

| 2200 | 2185 | 6 | 9 | 235 | 1.2 | ≥10 | 3.5 |

| 2400 | 2385 | 6 | 10 | 235 | 1.2 | ≥10 | 3.5 |

| 2600 | 2585 | 6.5 | 10 | 240 | 1.2 | ≥10 | 3.5 |

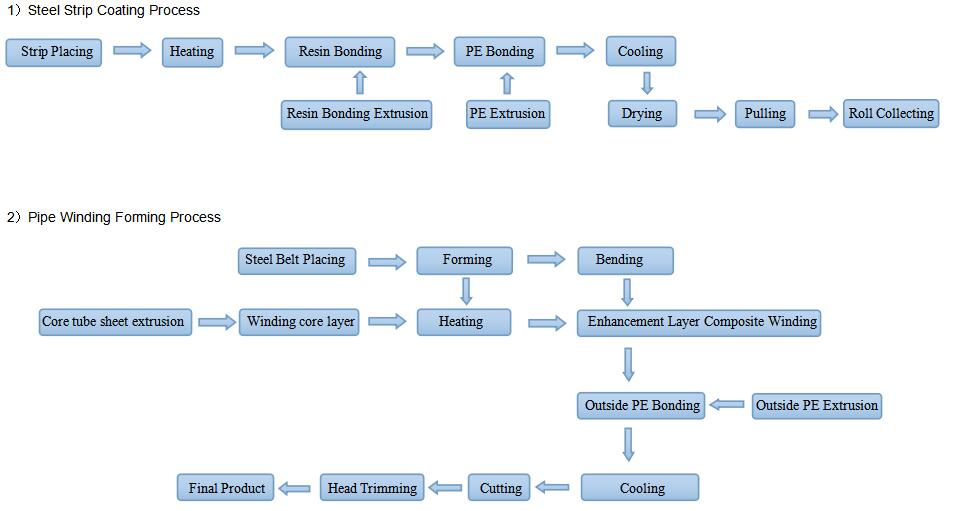

Making Process

Light weight compared with steel pipe or concrete pipe, easy to install.

Saves money on installation costs due to its long length and easy transport.

PRODUCTS

NEWS

CONTACT US

Mob/Whatsapp: +86-15036793056

Phone: +86-37962306300

Fax: +86-37960406316

Email: export@lysinopipe.com

Add: National New & High Tech Industry Development Zone ,Luoyang ,CHINA