CABLE PROTECTION TUBE

CABLE PROTECTION TUBE

- Product ID:CABLE PROTECTION TUBE

- Phone: +86-15036793056

- WhatsAPP: +86-15036793056

- Email: export@lysinopipe.com

- Payment term: TT/LC/Western union

- send inquiry

CPVC and MPP-Best Solution of Cable Protection

CHLORINATED POLYVINYL CHLORIDE (CPVC)

CPVC tubing comes in nominal sizes ranging from 1/2 to 2 in. copper tube size (CTS), and pipe sizes ranging from 1/2 to 24 in. (Sch 40/80) iron pipe size (IPS). CPVC tubing is SDR11 (1/2 to 2 in.) with standard hydrostatic pressure ratings of 400 psi at 73ºF (2,750 kPa at 23ºC) and 100 psi at 180ºF (690 kPa at 82ºC). Consult the specific CPVC pipe manufacturer's literature and listings for appropriate pressure ratings. CPVC tubing and pipe are sold in straight lengths.

Definition: is PVC (polyvinyl chloride) that has been chlorinated via a free radical chlorination reaction. CPVC is produced by adding chlorine to PVC in a water slurry or fluidized bed chlorination process. The chlorination reaction is initiated by ultraviolet light. The chlorinated PVC is compounded with ingredients necessary for the desired properties for further processing. The chlorine added to PVC gives CPVC higher temperature performance and improved fire and corrosion resistance.

Overview: CPVC is a high-temperature plastic pressure piping system introduced for potable plumbing in 1959. It has also been used extensively in fire sprinkler systems since 1985. This material is also used for many industrial and process piping applications. CPVC pipe is available in nominal sizes from 1/2" to 24" and is approved in all model plumbing and mechanical codes across the United States and Canada. In addition, CPVC pipe and fittings from select manufacturers are listed for light hazard fire sprinkler systems, as defined in NFPA 13, 13R and 13D standards.

CPVC Advantages

- Safety of potable water and long-term reliability

- Resistance to corrosion, tuberculation, deposits

- Chlorine and chloramine resistance

- Lightweight, easy to transport

- Available in wide range of sizes

- Noise and water hammer resistance

- No scrap value, avoiding jobsite theft

- Durability and toughness to survive jobsite installations

- No flame used for joining, solvent cement joints

- Universal compatibility of pipes/fittings

- Professional installed appearance

- Hot- and cold-water plumbing distribution, residential and commercial

- Fire protection: One- and Two-Family Dwellings and Manufactured Homes (NFPA 13D), Low-Rise Residential Occupancies (NFPA 13R) and Light Hazard Occupancies (NFPA 13)

- Reclaimed water piping (purple pipe)

- Chilled water piping

- Hydronic piping and distribution (radiators, fan coils, etc.)

- Suitable for many industrial and process piping applications

- TN-62 - Suitability and Fitness of CPVC Piping Systems for Commercial Building Applications

- Recommendation H – Direct Connection of Plastic Piping Materials to Tankless Water Heaters

- Installation of CPVC Fittings With and Under Concrete Slabs

- Presentation: Plastic Pressure Piping Materials for Plumbing & Mechanical Applications

- ASTM D2846 - Standard Specification for Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Hot- and Cold-Water Distribution Systems

- ASTM F441 - Standard Specification for Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Pipe, Schedule 40 and 80

- ASTM F442 - Standard Specification for Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Pipe (SDR-PR)

- ASTM F438 - Standard Specification for Socket-Type Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Pipe Fittings, Schedule 40

- ASTM F439 - Standard Specification for Chlorinated Poly (Vinyl Chloride) (CPVC) Plastic Pipe Fittings, Schedule 80

- ASTM F493 - Standard Specification for Solvent Cements for Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Pipe and Fittings

- CSA International B137.6 - CPVC Pipe, Tubing and Fittings for Hot and Cold Water Distribution Systems

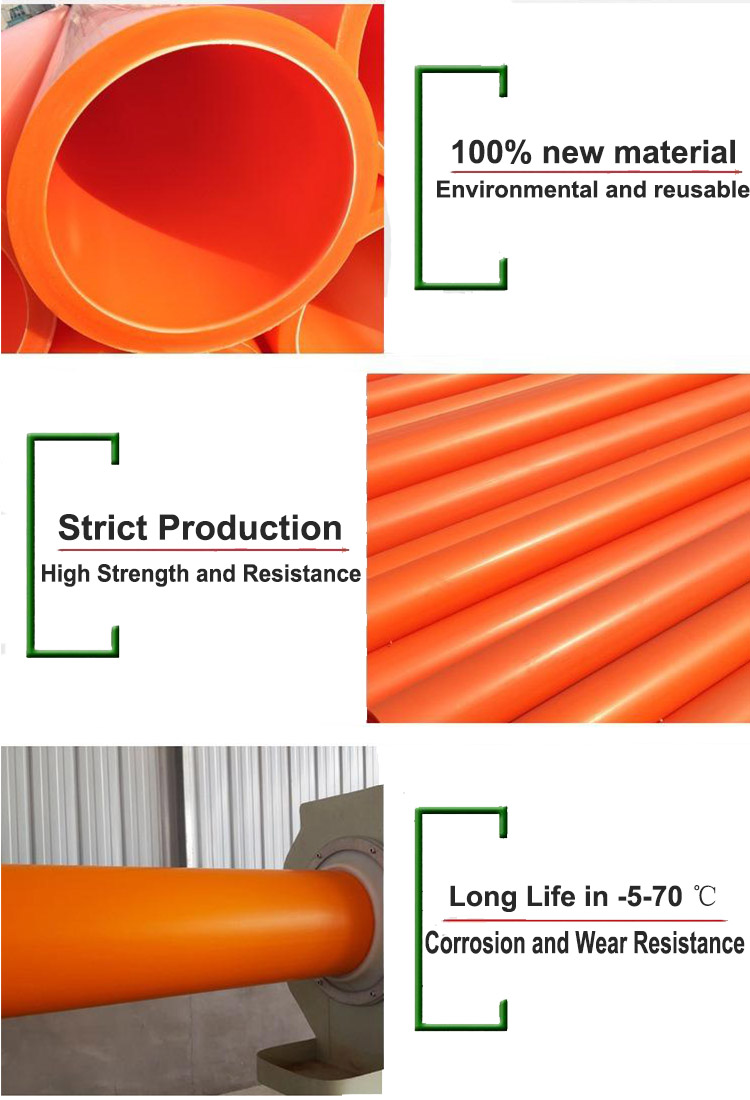

MPP power pipe products:

MPP power pipe with modified polypropylene as the main raw material, is not a large number of dredging, excavation and destruction of the road, in the road, railway, building, river bed, such as the laying of special sections of the pipeline, cable and other construction projects. Compared with the traditional "digging method, trenchless pipe engineering more adapted to the requirements of environmental protection, because the traditional construction caused by the removal of dust, traffic congestion and other disturbing factors, this technology can also be unable to carry out excavation work in laying pipelines, such as Heritage Conservation District, downtown, and crops farmland protection areas, highways, rivers etc..

The utility model is characterized in that the utility model has the advantages of high temperature resistance and external pressure resistance, and is suitable for the 10KV high voltage transmission line cable pipe material.

110mm ~ 250mm, divided into ordinary and enhanced type. The ordinary type is suitable for the construction of the excavation and the non excavation through the construction of the buried depth of less than 4M of the project; strengthen the application of non excavation through the construction of the depth of more than 4M. This product has achieved good social and economic benefits through the national chemical building materials testing center testing.

Two, MPP power pipe applicable scope:

MPP power pipe can be widely used in municipal, telecommunications, electricity, gas, water, heat and other pipeline engineering.

MPP electric power pipe for trenchless horizontal directional drilling in urban and rural areas, and power pipe engineering for open excavation.

MPP power pipe urban and rural trenchless horizontal directional drilling sewage drainage pipe engineering. Industrial wastewater discharge project.

Three, MPP power pipe superiority

1, MPP power pipe has excellent electrical insulation.

2, MPP power tube has high thermal deformation temperature and low temperature impact performance.

3, MPP power pipe tensile, compressive performance is higher than HDPE.

4, MPP power tube light, smooth, friction main small, hot fusion welding butt.

5, MPP long term use of power pipe temperature 5 ~ 70 C.

6, MPP pipe construction notice

L MPP power pipe pipe transportation, construction process is strictly prohibited any throw throw, impact, characterization, exposure.

L MPP power pipe hot melt butt when the two tube axis to be aligned, end cutting to vertical flat.

L MPP power pipe processing temperature, time, pressure, depending on the climate of the corresponding adjustments.

L MPP power tube bending radius should be not less than 75 pipe diameter.

PRODUCTS

NEWS

CONTACT US

Mob/Whatsapp: +86-15036793056

Phone: +86-37962306300

Fax: +86-37960406316

Email: export@lysinopipe.com

Add: National New & High Tech Industry Development Zone ,Luoyang ,CHINA